For some time I’ve wanted an easier way of reverse mounting a bowl for finishing the bottom, and have seen several options. Seeing that you can build several of these options, I knew that was the route I would take, as I could not justify spending around 100 bucks for a set of jaws.

I’ve considered the Longworth chuck and the donut chuck, but recently I saw some homemade jumbo jaws for a scroll chuck, and thought I could make a set of these for my Talon chuck.

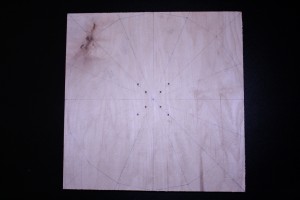

The first thing I did was to cut a square of 3/4″ plywood. My two lathes both have a 12″ swing, so I made the square 11″. Since the Talon chuck has about a 1 1/2″ range of travel, I figured this would give me enough travel to accommodate any size bowl up to around 10″ in compression mode, and up to the full 12″ in expansion.

I laid out cutting and drilling guide lines, first by drawing from corner to corner, then from side midpoints, and then bisecting the resulting 45 degree angles, resulting in 8 guide lines.

I couldn’t find a compass, so I just marked 5 1/2″ from the center down each line, and connected the dots. Then I cut the square into 4 smaller squares on the tablesaw, and rough-cut the corners on the bandsaw.

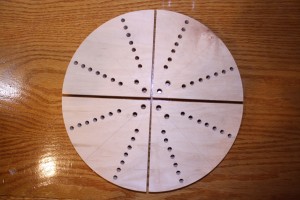

Next I laid out the mounting holes using a set of jaws to locate the positioning. I then drilled them on the drill press.

I then mounted them on the chuck, and retracted it all the way in. I mounted it on the lathe, and turned the jaws round, and to a diameter that would allow about an inch of travel before hitting the bed. I also turned grooves in the face of the jaws, spaced at 1/2″.

I removed the jaws, and then drilled holes along the pin layout lines, spaced at 1/2″.

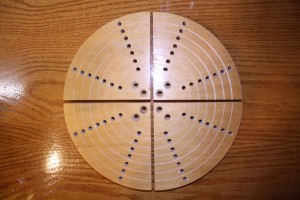

Here is a shot of the back of the jaws.

And a shot of the front.

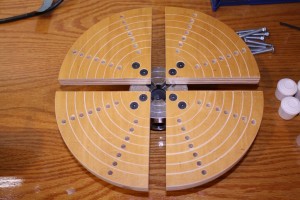

Here are all of the parts of the jaws.

The jaws being attached.

Jaws attached.

I made the mounting pins by turning a piece of maple down to 7/8″ and drilled a 1/4″ hole in the center, and parted off 1″ lengths. I used 2″ x 1/4″ carriage bolts, and 7/8″ chair foot bumpers to finish the pins.

The correct holes to use is determined by expanding the jaws out an inch, and then placing the bowl centered on the jaws. Here I am using a bowl that I originally turned probably 5 or 6 years ago, but never got the base completed. It was green when I turned it, and has warped considerably.

The pins are attached with washers and nuts on the back of the jaws.

Here’s a shot of the chuck with jaws and pins attached.

The bowl is then mounted in the chuck. Considerable pressure was applied, and it was held very securely.

Here it is mounted on the lathe. The tailstock was used for additional security.

I turned most of the bottom before removing the tailstock. I used my homemade carbide tool for most of the bottom.

I finished the rest of the bottom.

And then sanded and finished it.

Once it was complete, I buffed the entire bowl. It turned out pretty well.

Once again….you saved the day! Another project I have been putting off.

Don, glad you like it. I have been putting this off for about 2 years, finally just did it. 🙂

Japie

Thanks for the extenda chuck plans.I am on way to make my own.

So much simpler than a longworth and a whole lot cheaper than a commercial set up. Thanks for sharing…

Brian, yeah, I’ve thought about the Longworth, but it sure seemed easy to goof up.

Do you mount the bowl with some of the supports not attached and then mount the last few and tighten it. Or do you leave all supports loose so you can fit the bowl on it and then start to tighten them to secure the piece.

Do you have a problem when turning that it is not running true and if so how do you fix that?

Alan, I tightened them all the way. I think there is enough give in the rubber chair feet to compress enough. That first bowl I finished was pretty warped, the bumpers held it pretty well. I think the only thing I think may be needed is to shim under the rim if it is warped enough.

It didn’t run very true, but I only turned the very bottom down, I didn’t go up the side at all. I was able to sand it pretty well at slow speed.

I made something like that but made the plugs a little longer and larger in diameter and put 1″ clear tubing over the wooden plugs

That’s a great idea. I’ve seen longer posts, but wasn’t sure what to put over them. Tubing sounds like a great solution. Thanks!

Very well done.

Thanks!

I really like the mounting pins using turned maple shafts. The slight taper to the outsides of the chair foot bumpers would appear to enhance the gripping power. Definitely my next home-made tool addition as soon as I can get to the hardware store for the bumpers.

Good idea, well illustrated. Keep up the good work.

-Floyd

Thanks, Floyd!

I have often wondered about such things as this being possible. I have not turned for many years, but have started back just recently. Have two old lathes, looking at the different models for a new one also. one of my old ones is very, very old. I have known of it for 60 years. I am in the process of building ways etc. to get it back into operation. When it was operating it was on large wood beams. Enjoy your article very much. Think bowl turning could easily become my passion. Sincerely Gavin Trousdale

Yes sir, it can be very addicting.

I live in Minnesota and am currently in Alabama until the end of the first week in April. I do not have a printer with me, will this article still be accessible at the end of this time frame? My chuck is forien made and the threaded fastening holes do not match the existing large bowl chucks available for around $100.00. The slowest RPM on my varible speed lathe is 710, will this be to fast for a 12″ dia. bowl?

Hi Jerry,

The article will be there, I am not planning on removing it. I’m hoping to get more articles up in the near future.

I am no bowl turning expert, I believe that is the slowest speed I have on my 12″ Jet as well. I am able to rough down bowl blanks that I cut with a chainsaw that are right at the lathe’s limit, so I would have to say no, it’s not too fast. Just have to try to get it balanced as best as you can.

Brilliant! Not only does this save money, it also allows you to customise the jaws to suit the project being worked on.

I made mine out of 1/2 inch plywood with “formica” on both sides. I coated the posts with several coats of liquid plastic. I use a Shopsmith, w/speed reducer, so I can run at very slow speed if I need to. My setup works well for me.

Thank you for posting this! I am in the process if making my own set based on your instructions. I’m using 1/2″ poplar plywood, and I’m wondering about the screws that attach to the chuck. Do you use the same screws that cone with your talon chuck, or did you have to use longer screws? I have original screws, and even after countersinking I feel like I don’t have enough bite to be comfortable. Thanks!

Hi Jason,

I bought new screws, they’re about a half inch longer than the screws that came with the chuck. I just picked them up at the hardware store. Stock screws for the Talon are M4 x 16, I believe the ones I got are M4 x 26.

I think I see what you did… I took the screws from the jumbo jaws I have, the ones that hold the rubber nubs in place. These are long enough, actually almost too long for 1/2″ plywood. Am I right?

I already had a set of store bought Jumbo Jaws but used a simmilar process when they were not big enough, only thing I did different really was I used the store bought jaws as a backing plate and mounted the home made plates onto them for extra support. I realize that 3/4 ply wouldn’t need much in the way of extra support but I tend to go with the theory that when things are spinning at high speeds more is better.

I agree. I’ve seen some with 1/2″ ply, but didn’t think that was solid enough.

Bill,

Thanks for the great article. I made a 24′ set for my lathe and used 11 ply 3/4 inch wood. I find that mounting them to the empty chuck a bit variable (not 100% flat) so I am tinkering with adding a spacer/backer that I can attach thru the plywood and then thru a #5 set of jaws (Stronghold Chuck). This would also alleviate some of my suspicion of how strong the wood is down near the chuck mounting holes themselves. Also, I went with the tubing over a turned dowel. This adds extra grip because the clear plastic tubing is just a bit soft, letting the turning “sink into” the post for extra grip.

The idea is great and your step / step instructions are very good. Thanks for sharing and please continue.

I have recently built a new tool holder for my turning tools / chucks / jaws / etc. If you want I can send you a photo. Just post a location to send the info.

Cheers,

Tom in Alaska

Thanks, Tom!

I guess ignorance is bliss, I saw the Longworth chuck and thought about how I hate changing the jaws on my 4 jaw chuck So off I went to the web, found the Longworth instructions and just did it. The radius routs look really complicated, they’re not! The hardest part was clamping the two disks for the routing. I added a permanent $8 face plate so there’s no set up, just spin in on and turn the wing nuts.

I’m thinking of making a pattern of 1/2″ thick plywood with the radius cuts at 1/2″ wide, thus I could add a 1/2′ inch collar to the router with a 1/4″ up cut spiral and this would eliminate all the trammel pivots needed, just let the bushing follow the radius with three or four plunges and put it together.

Don’t try it because of this suggestion, I’ll waste the time and wood and let you know how the pattern idea works. If it works a club could turnout Longworth chucks all day long.

Very cool – I like this jig. Making one today.

Thanks Bill.

I’m new to this sort of thing. Until recently, I had not used a lathe for the best part of 50 years when I was at school, and as far as I know chucks for woodturning had not even been considered at that time. Faceplates and centres were all we had. I have just ordered my very first chuck, and will certainly be making one of these useful devices in due course.

Can I say that Bill’s idea and the wonderful way in which he presents it step-by-step, are informative, instructional, educational, inspirational, but one thing they are not is cool. Please strike this overused, meaningless word from any future post unless it refers to a state of thermal energy creating a temperature somewhere

between warm and cold.

The screws are M6 X 1.0mm (pitch). As for the length, I got 30 mm (1.2″) that can be cut down if necessary. Amazon has them -2o pcs. for $8.82 with free shipping.

I was thinking of buying a set of cole jaws and now I don’t have to. Thanks to your easy to follow post. Thanks a lot. James