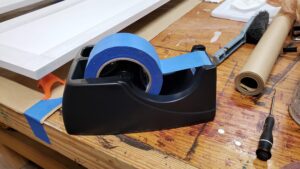

We’ve all heard that using painter’s tape to mask off parts for gluing can save a lot of time later on when we are unclamping and cleaning up the squeeze-out. But how many of us actually take the time to do that? Continue reading

-

Search Our Site

-

Subscribe to Our Newsletter

Categories

Recent Posts

DEWALT 20V MAX Cordless Battery Powered Pruner

?The problem and the solutionRead More »

Into Each Life a Little Rain Must Fall

When it’s too little you have to step up your …Read More »

Happy Mother’s Day

Happy Mother’s Day. At our house we say that with …Read More »

3D Printed M12 Drill Slatwall Holder

Continuing on the SlatWall custom tool holders, I have designed …Read More »

3D Printed Milwaukee M12 Charger Slatwall Mount + Free Plans

I have some slatwall in the garage and in my …Read More »

Recent Comments

Archives

- November 2024

- August 2024

- May 2024

- April 2024

- March 2024

- February 2024

- January 2024

- September 2023

- August 2023

- July 2023

- June 2023

- May 2023

- April 2023

- March 2023

- February 2023

- January 2023

- February 2019

- August 2018

- July 2018

- September 2015

- March 2015

- February 2015

- January 2015

- December 2014

- November 2014

- October 2013

- August 2013

- January 2013

- August 2012

- February 2012

Past Newsletters

- August 16, 2024 Borouz Woodworking New Blog Posts

- May 10, 2024 Borouz Woodworking New Blog Posts

- May 3, 2024 Borouz Woodworking New Blog Posts

- April 26, 2024 Borouz Woodworking New Blog Posts

- April 12, 2024 Borouz Woodworking New Blog Posts

- April 5, 2024 Borouz Woodworking New Blog Posts

- March 29, 2024 Borouz Woodworking New Blog Posts

- March 22, 2024 Borouz Woodworking New Blog Posts

- March 8, 2024 Borouz Woodworking New Blog Posts

- February 16, 2024 Borouz Woodworking New Blog Posts

- February 2, 2024 Borouz Woodworking New Blog Posts

- January 26, 2024 Borouz Woodworking New Blog Posts

- January 19, 2024 Borouz Woodworking New Blog Posts

- September 8, 2023 Borouz Woodworking New Blog Posts

- September 1, 2023 Borouz Woodworking New Blog Posts

- August 18, 2023 Borouz Woodworking New Blog Posts

- August 11, 2023 Borouz Woodworking New Blog Posts

- August 4, 2023 Borouz Woodworking New Blog Posts

- July 14, 2023 Borouz Woodworking New Blog Posts

- July 7, 2023 Borouz Woodworking New Blog Posts

- June 16, 2023 Borouz Woodworking New Blog Posts

- June 2, 2023 Borouz Woodworking New Blog Posts

- May 19, 2023 Borouz Woodworking New Blog Posts

- May 12, 2023 Borouz Woodworking New Blog Posts

- April 28, 2023 Borouz Woodworking New Blog Posts

- April 21, 2023 Borouz Woodworking New Blog Posts

- April 7, 2023 Borouz Woodworking New Blog Posts

- March 31, 2023 Borouz Woodworking New Blog Posts

- March 24, 2023 Borouz Woodworking New Blog Posts

- March 17, 2023 Borouz Woodworking New Blog Posts

- March 10, 2023 Borouz Woodworking New Blog Posts

- March 3, 2023 Borouz Woodworking New Blog Posts

- February 25, 2023 February 25, 2023 Newsletter

- March 20, 2019 Check Out Our New Galleries! - Borouz Woodworking

- September 4, 2018 Corn Cob Pens! - Borouz Woodworking

- August 28, 2018 Borouz Woodworking Newsletter

- August 6, 2018 Borouz Woodworking

- August 3, 2018 Borouz Woodworking Newsletter

Yea, that’s right I said it. We have tried so many different “ideas” to get the shop organized. Keeping it that way is another story. One of the biggest issues has been not knowing where things are when we need them. Now in our defense it’s been a crazy few years since the shop was built. For a while we actually lived in two different states and we were doing a complete build out of a local theater. So tools were being transported across state lines and or repurchased. Things were in storage or packed away in boxes. You get the idea. Once we had everything moved back into one state things didn’t get unpacked or they were “put away” just to get them out of boxes and in the building. Life. Gets. Complicated. Now it’s time to start thinking about getting some sort of control without having to spend a lot of money.

Yea, that’s right I said it. We have tried so many different “ideas” to get the shop organized. Keeping it that way is another story. One of the biggest issues has been not knowing where things are when we need them. Now in our defense it’s been a crazy few years since the shop was built. For a while we actually lived in two different states and we were doing a complete build out of a local theater. So tools were being transported across state lines and or repurchased. Things were in storage or packed away in boxes. You get the idea. Once we had everything moved back into one state things didn’t get unpacked or they were “put away” just to get them out of boxes and in the building. Life. Gets. Complicated. Now it’s time to start thinking about getting some sort of control without having to spend a lot of money.